pcd diamond copper wire drawing die

Copper plated wire drawing die

In the wire industry, the copper wire drawing process is widely used, and the copper wire drawing liquid is generally used as a drawing lubricant to achieve high speed and efficient production. In actual production, the following problems often occur:

(1) The copper-plated steel wire ion reacts with the fatty acid anion in the pulling liquid to form a water-insoluble divalent copper-plated steel wire soap. These copper-plated steel wire soaps are clogged in the drawing die, resulting in the emulsion not being completely brought into the die with the copper-plated steel wire, and adhered to the surface of the copper-plated steel wire through the wire drawing die, which causes physical lubrication failure;

(2) The copper-plated steel wire ions also react with the unsaturated fatty acids in the drawing liquid to form a dark green sticky substance, an aliphatic polymer, which forms a rapid separation from the water-based system and floats on the surface of the oil pool. The formed copper-plated steel wire soap together attracts the active fatty acid boundary lubricant, which leads to emulsification failure, lubricant splitting, lubrication failure and emulsion failure, causing broken wire and shrinkage, which seriously affects the quality and production of copper-plated steel wire. Efficiency, and even the drawing line will be forced to stop production, bringing direct economic losses to the enterprise.

Therefore, how to solve the problem of shrinkage and broken wire in the production of copper-plated steel wire drawing is a key technical issue in the research and development of copper-plated steel wire drawing lubricating fluid. The key technology of copper-plated steel wire drawing lubrication is the shrinkage and broken wire in the drawing process of copper-plated steel wire, which seriously affects the quality of copper-plated steel wire and reduces the production efficiency. The technical problem of solving the shrinkage and broken wire is to solve Lubrication problems during the drawing of copper-plated steel wire.

The copper-plated steel wire drawing is not exactly the same as the general metal cutting lubrication mechanism. The lubrication performance cannot be simply emphasized. The compatibility of the emulsion stability, cooling and lubrication effects needs to be considered comprehensively.

Only the balanced copper-plated steel wire drawing lubricating oil can overcome the broken wire and the shrinkage wire and improve the production efficiency. In the copper wire steel wire drawing lubricant, the first thing to consider is the stability of the emulsion; in the fine and small wire drawing lubricants, the balance of cleaning and lubrication is emphasized; in the fine wire drawing lubricant, the focus is on settlement and cleaning. match. Tall oleic acid diethanolamide differs from traditional coconut oleamide in that it contains fatty acids and about 30% rosin compared to the usual coconut oleic acid, which is very important and provides enhanced fatty acid applications. The performance guarantees the balance of lubrication and cleaning. It is used as an emulsifier. It has fast emulsification speed, excellent lubricity, good cleaning effect and wide adaptability to hard water. Therefore, the use of tall oil oleic acid diethanolamide in the copper-plated steel wire drawing liquid can improve the emulsion stability of the emulsion, the matching of cooling and lubricating effects, and the performance of the anti-copper steel wire soap, and solve the problem of high-speed copper-plated steel wire drawing and shrinking. The author of this paper, the distillation of tall oil and diethanolamine as the main raw materials, synthesized the tall oleic acid diethanolamide surfactant, and in the high-speed copper-plated steel wire drawing liquid for experimental research.

Contact us,

Tel: +86-13027628261

Email:admin@qediamonddie.com

Website: www.qediamonddie.com

评论

发表评论

QEDIAMONDDIE is a manufacturer in China and we produce wire drawing dies.

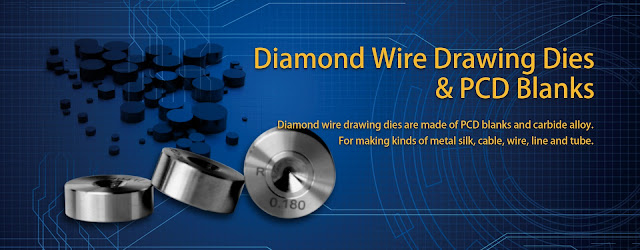

pcd dies

wre drawing dies

pcd mould

diamond mould

diamond dies

diamond wire drawing dies

official website: www.qediamonddie.com

email address: admin@qediamonddie.com

Contact Number: 0086-15537179206