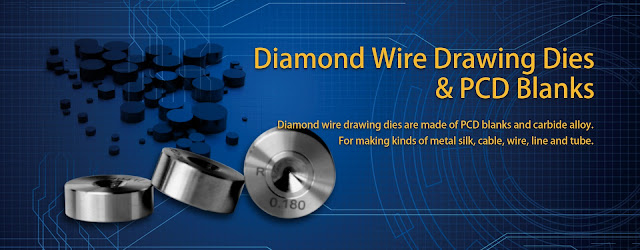

QEDIAMONDDIE tungsten carbide dies diamond dies wire drawing Product Description Natural diamond wire drawing dies Natural diamond wire drawing dies has excellent wear resistance and high quality surface finish, suitable for a variety of fine wire, drawing precious metal wire can reduce wear, improve wire surface finish, specification range 0.01-1.5mm. Mono diamond wire drawing dies Mono diamond’s feature is similar with Natural diamond. Drawing surface is very fine, good polishing. Hole can keep well in round shape when drawing. It is used for fine metal wires. Like copper, golden wire . silver wire and so on. Special shaped polycrystalline diamond mold Selection imported and domestic high-quality mold processing, support hexagonal, square, flat square, triangle, circle, and various special-shaped hole requirements, suitable for drawing copper flat wire, square wire, zipper flat wire, stainless steel special-shaped wire dr...